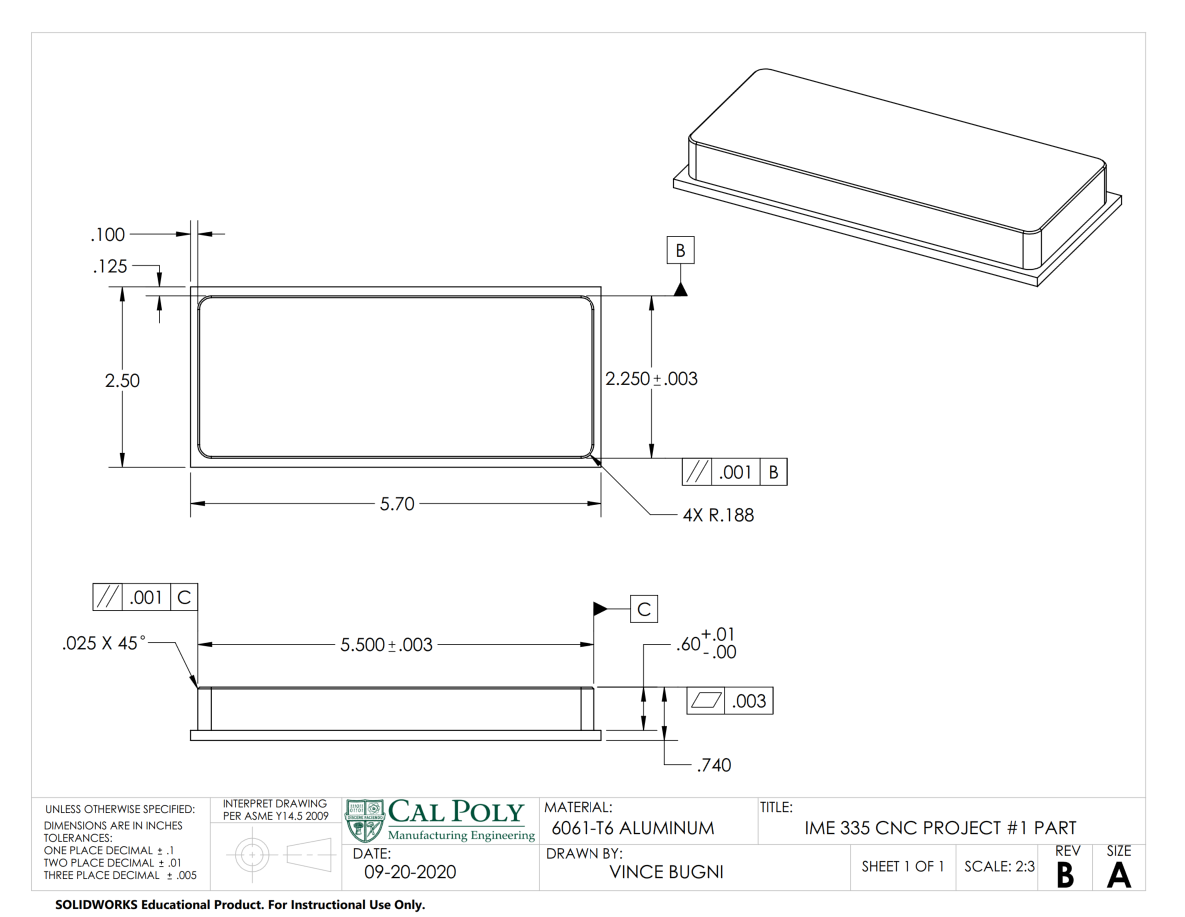

CNC Card Holder

Creating an aluminum business card holder from scratch.

School: California Polytechnic State University, San Luis Obispo, 2020

Skills: Mastercam, First Article Inspection (FAI), Metrology, G-Code, Solidworks, GD&T, CNC Operation

Materials: 6061-T6 Aluminum

The objective of this project was to create a business card holder while learning about G&M Code, Part Routings, First Article Inspections, CAM Software, and operating a Haas 3-Axis CNC mill.

First, the part was modelled in SolidWorks and a drawing was created with detailed GD&T, and a part routing was made for the whole part. The first CNC operation was written manually: face milling the bottom of the stock to flatten it and end milling the sides to create edge contours. Toolpath drawings were created, G&M code was written, and a CNC setup sheet was made. After the operation, it underwent a First Article Inspection Report (FAIR) using manual metrology tools to determine if it matched drawing specifications.

I used Mastercam to program the second CNC operation. In this operation the top of the Aluminum was milled flat using a face mill and the card pocket and keyway ramp were cut using end mills. The edges were chamfered with a 45 degree chamfer tool and the text was engraved using a ball end mill. Geometry was inspected again, but this time using a Zeiss Duramax CMM.